- HOME

- Solutions

-

Products

Products

- Bio-fermentation Equipment

- Reactor

- Rotary Evaporator

- Freeze Drying

- Wash & Clean

- Filling Machine

- Shaking Incubator/Incubator

- Air Clean Equipment

- Medium Preparation and Filling System

- Sterilization Equipment

- Refrigerated/Heating Circulator

- Air Compressor

- Peristaltic Pump

- Disinfection equipment

- Isolator

- Centrifugal Separator

- Water Purification System

- Water Testing Equipment

- Pharmaceutical Water Purification System

- Kjeldahl Protein Nitrogen Analyzer And Relevant Devices

- Moisture Analyzer

- Balance

- Grinder

- Portable X-ray Fluorescence Analyzer

- Benchtop X-ray Fluorescence Analyzer

- Drug Residue Testing

- Edible Oil Testing

- Agriculture

- Dumas Nitrogen Analyzer

- Lipid Oxidation Analyzer

- Microbiological Detector

- Mycotoxin Detector

- Organic Element Analysis

- Solvent Extraction

- Agricultural Residue Detector

- Gas Chromatography

- Microbial Sampling and Testing Equipment

- Air Quality Monitor

- Portable VOC

- Continuous Monitoring of Total Non-methane Hydrocarbons

- Exhaust Gas Sampler

- Soil VOC Detector

- Mobile Container Laboratory

- Low Temperature Preservation

- Molecular Biology

- Cryogenic Preservation

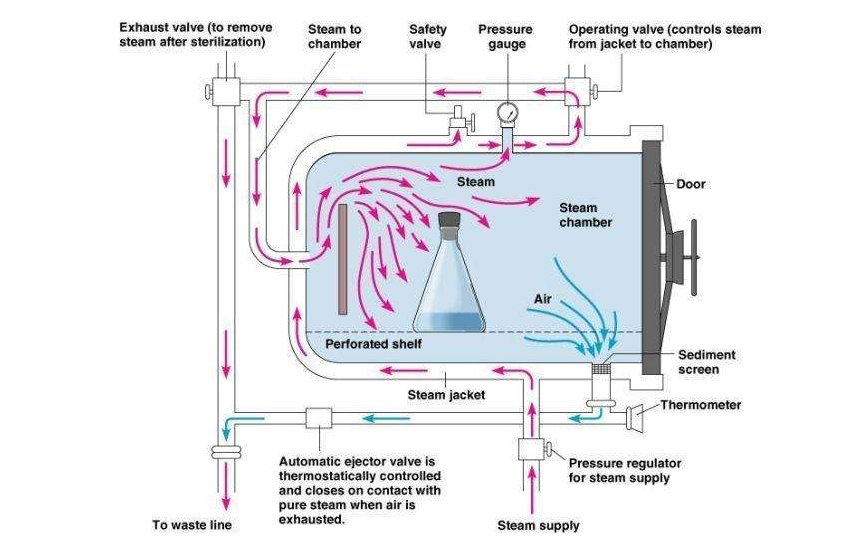

- Autoclave

- Spectrophotometer

- Oven

- Water Bath/Chiller

- Biosafety Equipment

- Biosafety Laboratory Room

- Centrifuge

- Pipette

- Stirrer & Mixer

- Shaker & Rocker

- Microscope

- Sample/Tissue Processing

- Microplate Reader

- Biochemical Analyzer

- Imaging System

- Titrator

- General Laboratory Instruments

- Colonometer

- Wiped Film Molecular Distillation

- Muffle Furnace

- Oil Centrifuge

- Analysis and Testing Equipment

- Spray Dryer

- Climatic Simulation Equipment

- Pharma Industry

- Clean Room/Purification Project

- Distillation & Purification

- Measurement and Analysis

- Hazardous Material/Safe Storage

- Mining

- Muffle Furnace

- Water Distiller

- Gas generator

- Glove Box

- Microwave Digestion Equipment

- Service & Support

- Global Reference

- About Us

- Contact

一级标题

一级标题